Case Study – 01

Resolving silo planning to free up cash and improve product freshness

The problem

Our client had almost 9 months’ worth of finished inventory and no customers to buy it, let alone at a price that made profit. In the meantime, the factory was busy making even more product.

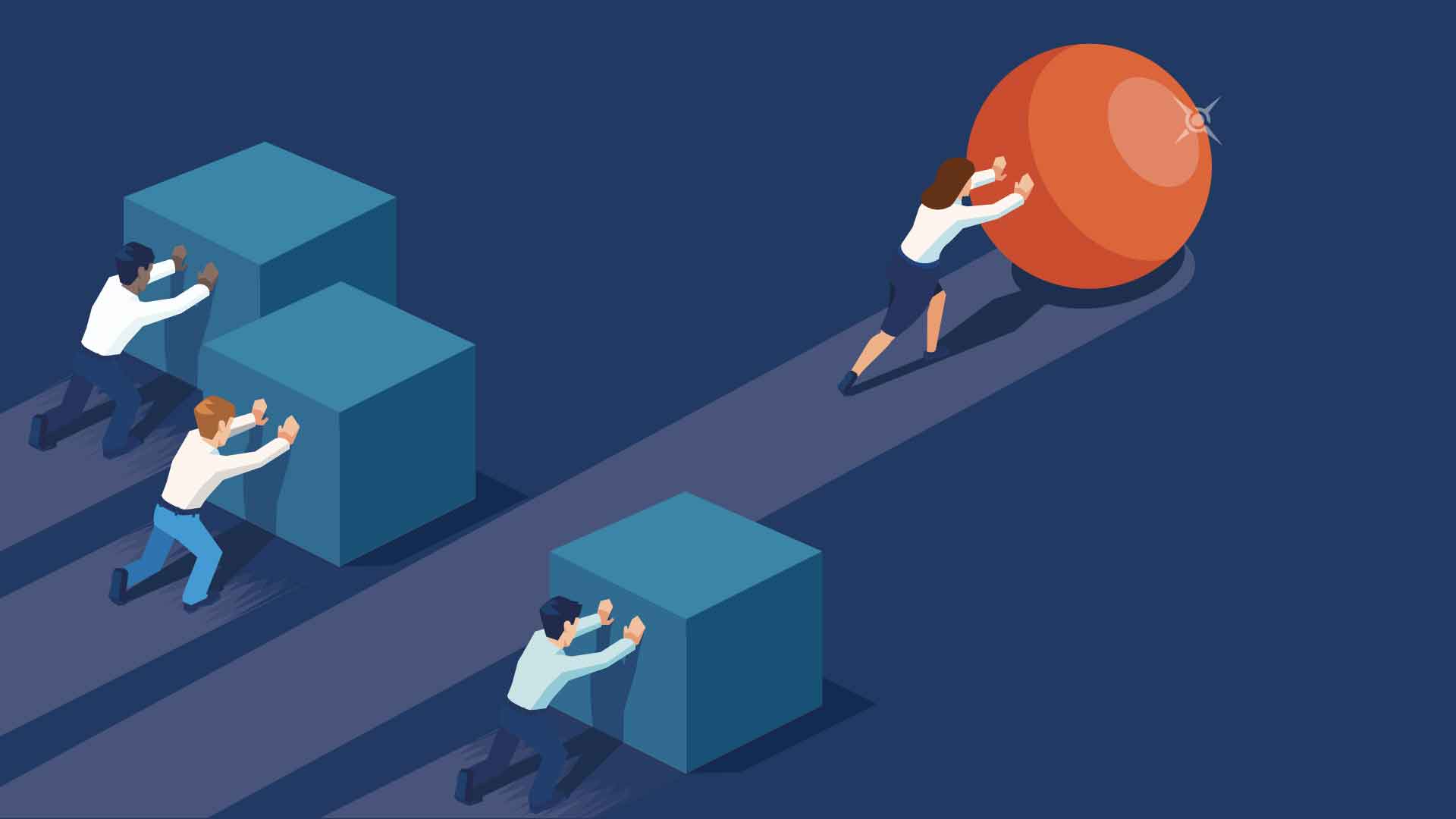

The business was working in silos with targets that made each silo look good but didn’t measure what was important to the business.

The background

The factory was measured on cost per unit, so was incentivised to make more product. This helped them spread fixed costs over more products, and a wholesale model meant that the factory got paid even if there were no retail customers.

The sales side of the organisation was measured on profit rather than units sold therefore measured the value of its sales forecast rather than the accuracy in units sold forecast. In addition, the sales team took sole accountability for excess inventory.

The combination of the factors resulted in stock that no-one wanted and no matter how many times Sales said “stop” the factory wouldn’t because it would drive up cost per unit.

The solution

After analysis, it was recommended that both sales and the factory be held jointly accountable for unsold inventory. This created a healthy tension – the factory expected an accurate forecast from sales which meant they could cost more accurately for making the right amount of product, and the sales team could expect the factory to produce at the lowest cost to ensure pricing was attractive to customers.

The Success

Within 12 months, the organisation was on a target of less than 3 months finished goods and no products sitting for more than 3 months. This freed up much needed cash and ensured product freshness.

Reflections

The first thing to consider is the people factor.

Persuading people to share accountability and shift mindset is harder than you think and requires an investment in learning to trust each other. People often just need to see the bigger picture and know that the end focus is the customer.

Little attention was paid to the full value of the chain from the factory silo. The stance was ‘it’s not my problem if sales can’t sell it all”. You then still have to cover the costs and make it possible to be profitable in a competitive market, so time was spent in increasing the build to order level. The entire exercise also involved marketing and product design. From what was a simple conversation about targets led to a full chain value analysis.